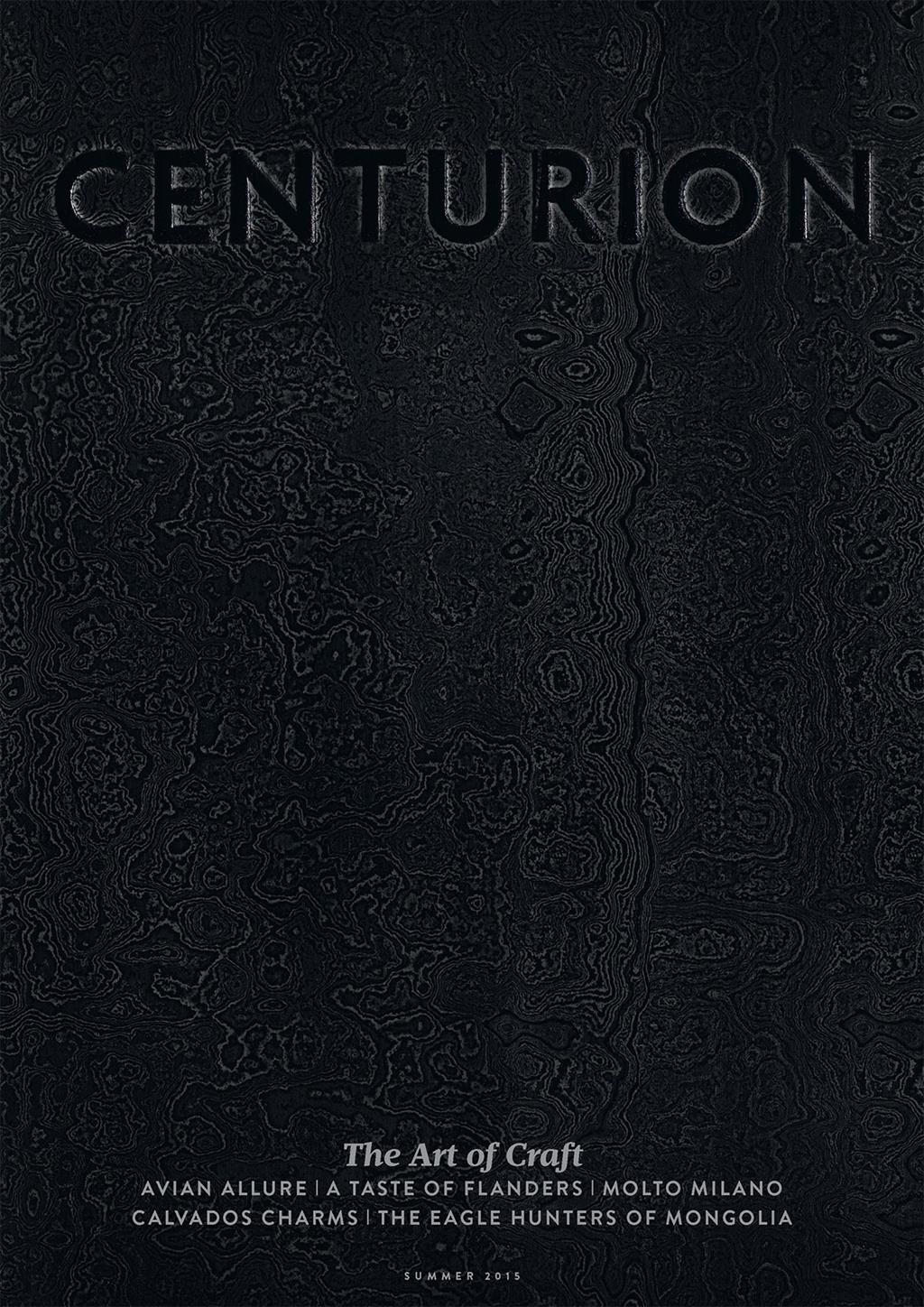

The Steely Black

We talk to Luca Distler of Messer Werk, the Bavarian bladesmiths responsible for the latest Centurion Magazine cover - a masterfully crafted sheet of Damascus steel

Electro-chemically etched onto hundreds of layers of hand-forged, beaten and finished steel, the Centurion moniker adorns the unmistakable imprint of Damascus steel for an edition that pays special attention to skilled artisans the world over.

Crafted by Bavarian bladesmith duo Messer Werk, who incorporate the exotic and time-consuming alloy into most of their bladed wares, have garnered a global clientele eager for products with provenance. Aesthetically intriguing and manually demanding, it stands to reason that this Centurion cover of steel should feature in such a way.

We spoke to Luca Distler, one half of Messer Werk, on the production of the cover, and the speciality of Damascus steel.

Describe the process and effort required to complete the Centurion cover.

This is tedious and arduous work, which demands full concentration during the entire 6-hour process in order to avoid making any mistakes.

[The] steel is folded over and over again, and making use of forge-welding techniques, [is] continually welded back together until we have approximately 600 layers of steel. When the material has been completed, the block of steel is then forged to the desired form. In this case, not a knife, but a steel plate.

Then the steel is elaborately smoothed out in an effort to remove the forging skin. The subsequent surface finish – a very fine polish-up to a grain size of 1000 – is then completed by hand. This is very important, so that the texture of the steel looks nice after its final acid bath.

I like producing a product with such a traditional and old technology and such beautiful material

Luca Distler, Messer Werk

In the final step, we applied an electro-chemical etching technique to etch the Centurion logo onto the surface. From the beginning to the end, [it] needed about 16 hours, or two work days, to complete the cover.

In an age of technology advancing production techniques, how important is it to maintain traditional practices?

It's very important! For us, it’s not about quantity but instead solely about quality.

Producing this level of quality, precision and individuality is only possible by hand. For our standards, there is no machine for surface finishing that matches our standards. For this, you need years of experience and know-how.

For you personally, why is the forging of Damascus steel so special?

I like working at the fire, [and] am fascinated by steelwork itself: I like producing a product with such a traditional and old technology and such beautiful material that still meets today's demands.